OUR PROCESS

-

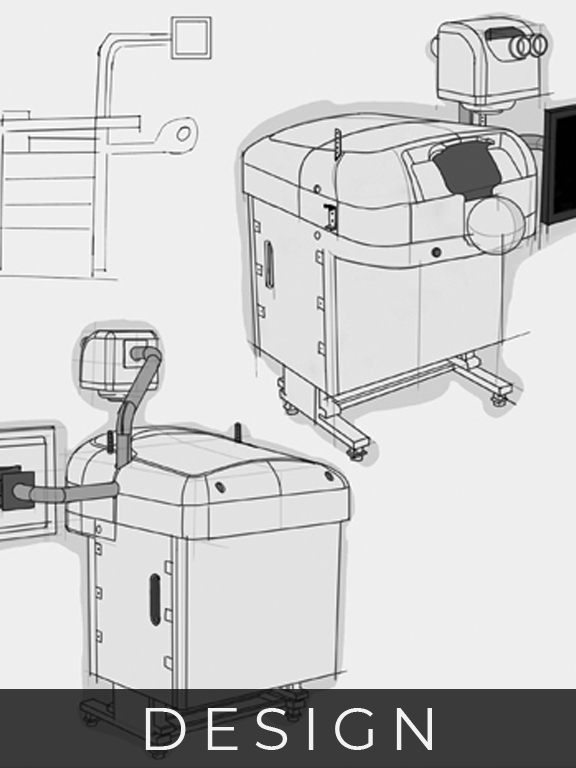

CONCEPT DESIGN AND DEVELOPMENT

-

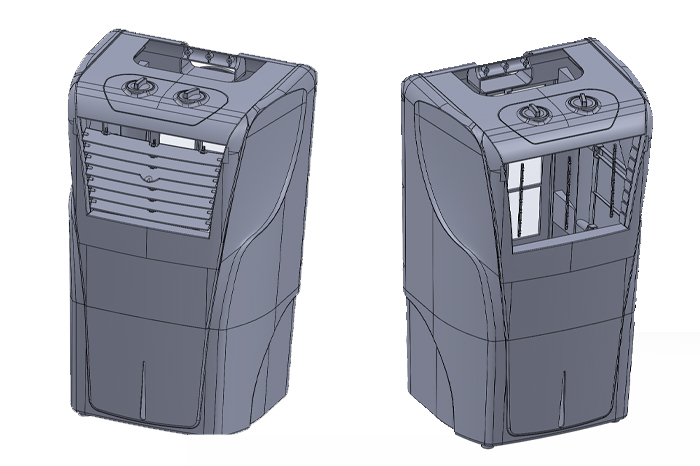

3D MODELING

-

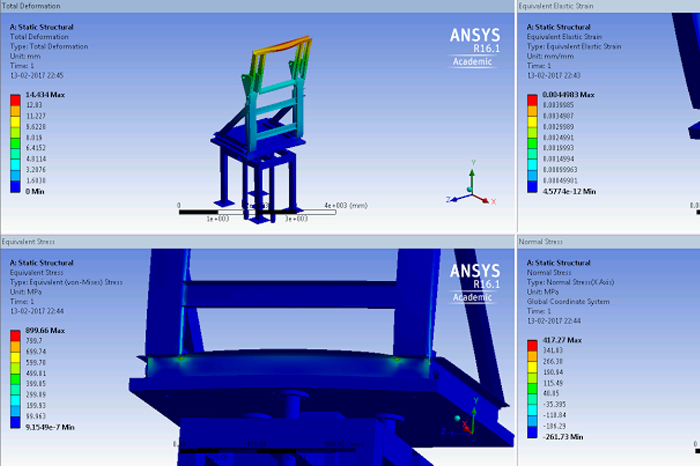

PRODUCT ANALYSIS

-

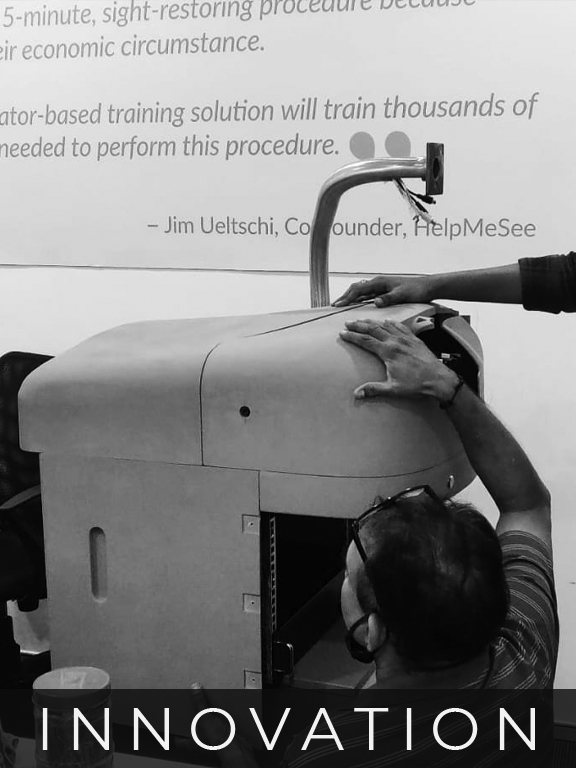

3D PROTOTYPING & QUALITY ANALYSIS

-

VALUE ENGINEERING & PRODUCT OPTIMIZATION

-

FINAL PRODUCT DELIVERY

| R & D of product design | Concept design and sketching | Material selection | Feasibility and manufacturability |

|---|

| Organic surface modeling | Product rendering and aesthetics development | 3D components modeling and assembly |

|---|

| Finite element analysis | Stress and deformation test | Mold flow analysis |

|---|

| Rapid prototyping | Quality inspection/ quality analysis of product prototype |

|---|

| Value engineering | Product optimization & recheck design |

|---|

| Value engineering | Product optimization & recheck design |

|---|

OUR SERVICES

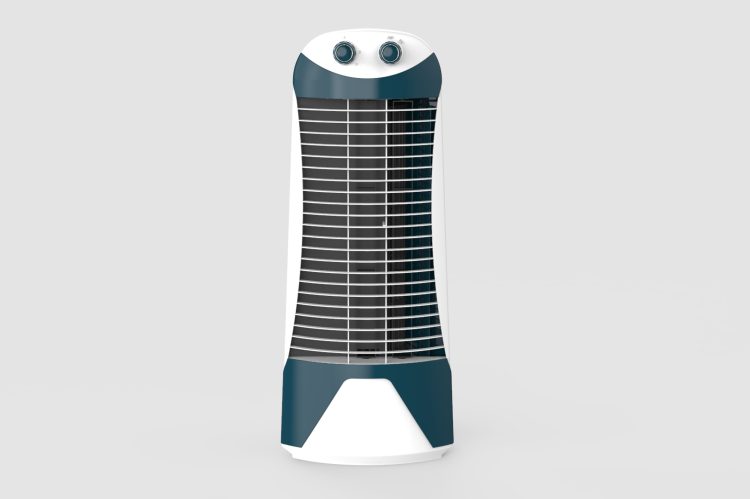

Industrial Product Design

Industrial Product Design is the professional service of designing, creating, and developing concepts and specifications that optimize the function, value, and appearance of products and systems for the the mutual benefit of both user and manufacturer.

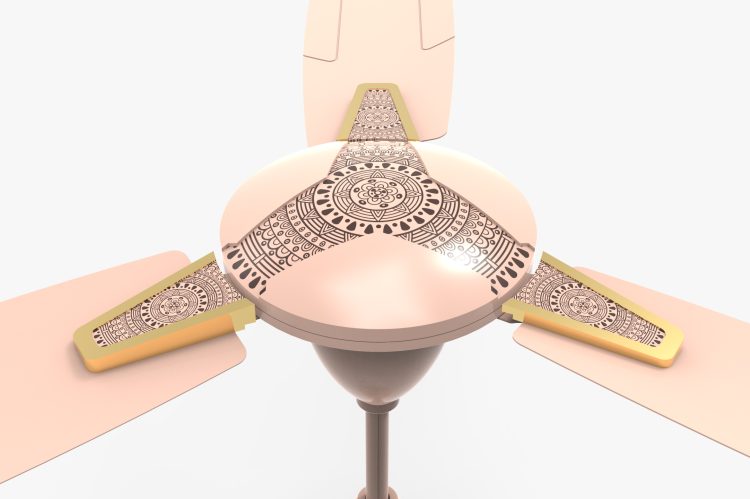

2D/3D-CAD Modelling

CAD modelling is tool used use to convert Ideas sketches from paper to Computer. There are 2 types namely, 2D CAD modelling – mainly used for drafting products, Detailed drawings and concept rendering second is 3D Modelling – used for 3D conversion of 2D drawings, Product Rendering, Product Analysis and Animation.

Engineering Services

Product engineering service is the utilization of various Hardware, Embedded, Software, and Prototyping services for the Design and Development of products. There are different phases of product engineering which includes using Product development tools, product development process, manufacturing consultancy, DFMEA design for manufacturing and assembly, and so on.

Product Analysis Services

Product Analysis is performed on the 3D CAD models in order to validate and optimize the design of the product. This is part of the value engineering of a product, wherein the design is tested with various boundary conditions added on the product, which replicated scenarios from the real world in order to understand product performance to those conditions.

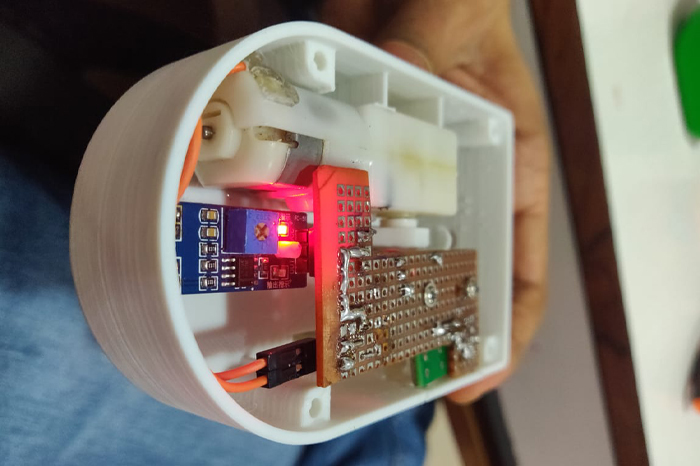

Embedded System and PCB Design

Embedded systems design is the process where hardware and firmware designers come together to build embedded systems from scratch. This involves PCB design, where the necessary components are connected to build functional circuits. To bring the electronics to life, the firmware is coded and then programmed into the microcontroller.

Packaging Design

Industrial design packaging is the process that allows your packaging to fulfill a wide range of functions. It has to be functional, holding your product, and enabling it to be transported and stored. It needs to stand out from your competitors’ packaging in some way, as well as appeal to customers in-store and online.

Animation

Animation means giving life to any object in computer graphics. It has the power of injecting energy and emotions into the most seemingly inanimate objects. 3D product animation is the procedure of making realistic three-dimensional CGI (Computer Generated Imagery) animation to visually represent the design, texture, color, configuration, assemblies and a well put together visuals of the product in its environment.